Table of Contents

Toyota RAV4 Code P1135: Complete Diagnostic and Repair Guide to Oxygen Sensor Heater Circuit Problems

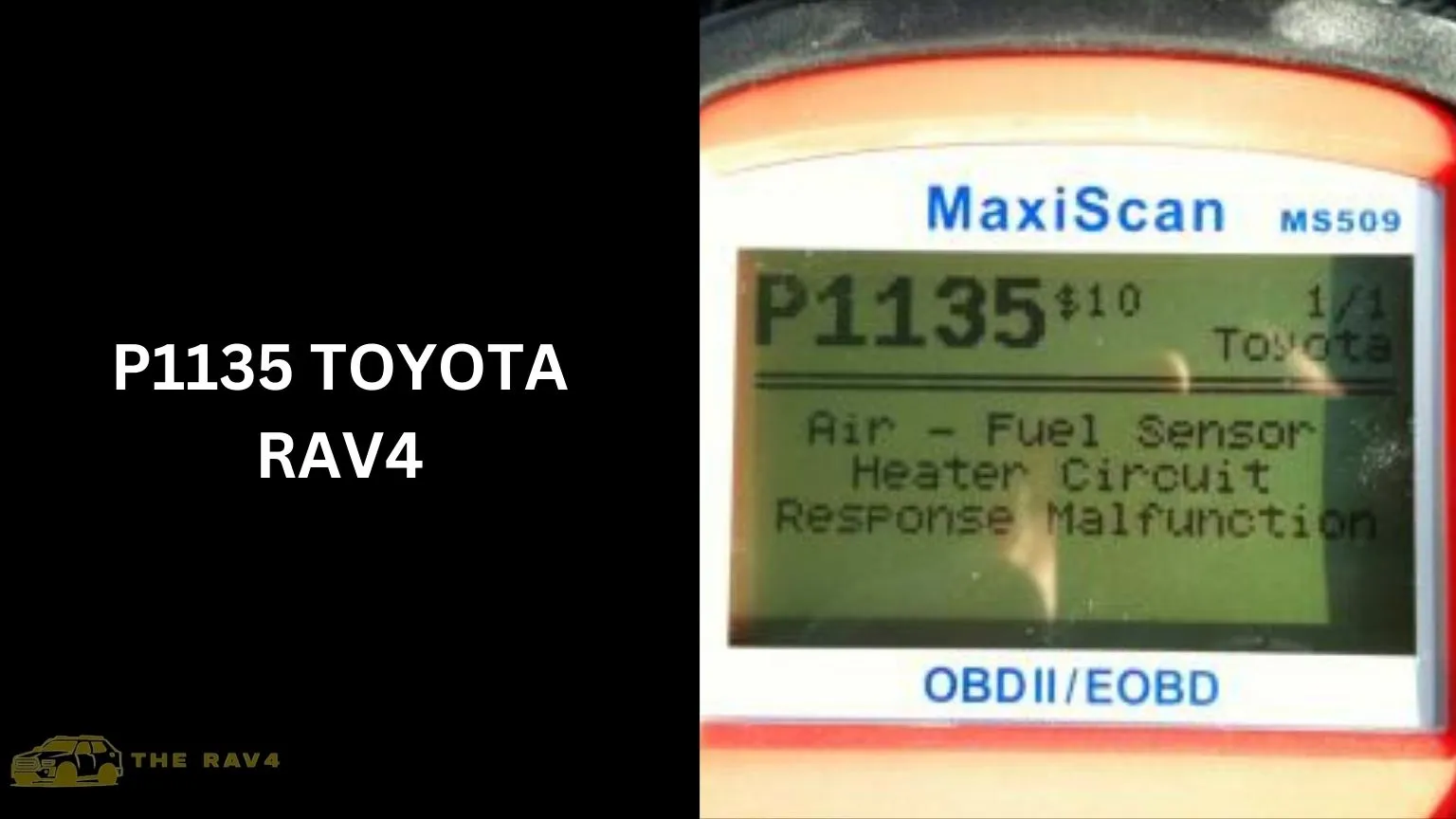

The P1135 diagnostic trouble code appearing on Toyota RAV4s represents one of the most common oxygen sensor-related problems affecting third and fourth-generation models. The code specifically indicates malfunction in the Air-Fuel Ratio (AFR) sensor heater circuit for Bank 1 Sensor 1—creating situations where the heating element responsible for bringing the sensor to optimal operating temperature fails preventing accurate exhaust gas measurement.

The Engine Control Module (ECM) depends on accurate sensor data for precise fuel delivery calculations affecting performance, fuel economy, and emissions compliance. Understanding P1135’s specific meaning versus related codes, recognizing symptoms beyond just illuminated check engine light, conducting systematic diagnosis identifying root causes, implementing appropriate repairs, and establishing realistic cost expectations proves essential for RAV4 owners encountering this common though often misunderstood trouble code.

The P1135 code’s prevalence on RAV4s—particularly 2006-2012 third-generation models though fourth and fifth-generation vehicles also experience this issue—results from combination of sensor design limitations and harsh operating environment. Heating elements prove vulnerable to thermal cycling stress and contamination. Sensors endure extreme temperature variations from ambient to 1,400°F+ exhaust temperatures creating expansion/contraction stress fracturing heating elements. Age-related deterioration affects most vehicles reaching 80,000-120,000 miles as original equipment sensors approach designed service life limits.

However, not all P1135 codes indicate actual sensor failure. Wiring harness damage, connector corrosion, ECM problems, or even temporary electrical glitches can trigger identical codes requiring thorough diagnosis rather than immediate sensor replacement that might prove unnecessary when simpler less expensive solutions would resolve problems.

This comprehensive guide examines every dimension of RAV4 P1135 code including detailed technical explanation of AFR sensor operation and heater circuit function, specific P1155 definition and how it differs from related codes, systematic symptom analysis, comprehensive diagnostic procedures, complete repair options, detailed cost analysis, generation-specific problem patterns, and proven preventive maintenance strategies. Whether you’re currently facing P1135 requiring immediate decisions, want to understand RAV4 reliability and common problems, or seek preventive knowledge avoiding future sensor issues, this guide provides complete accurate information enabling optimal outcomes.

Understanding Air-Fuel Ratio Sensors and Heater Circuits

Before examining P1135 specifically, understanding AFR sensor technology and why heating elements prove essential provides critical context for appreciating both the code’s significance and appropriate diagnostic responses.

AFR Sensor Function in Modern Engine Management

Air-Fuel Ratio sensors (also called wideband oxygen sensors or lambda sensors) represent sophisticated evolution beyond traditional narrowband oxygen sensors. They measure exhaust oxygen content across wide range enabling precise determination of actual air-fuel ratio rather than just simple rich/lean indication that older sensors provided.

The RAV4’s Bank 1 Sensor 1 (upstream sensor before catalytic converter) serves as primary fuel control feedback device. It continuously monitors exhaust oxygen concentration and reports to ECM that adjusts fuel injection quantity maintaining optimal 14.7:1 stoichiometric ratio where combustion efficiency and emissions control prove optimal.

This creates closed-loop control system where sensor feedback enables real-time fuel delivery corrections compensating for changing conditions. These include altitude, temperature, engine wear, and fuel quality variations that open-loop preset fuel maps cannot accommodate.

The sensor technology uses zirconia ceramic element generating voltage signal proportional to oxygen concentration difference between exhaust gas and ambient air. The voltage output varies from approximately 0-1.0 volts depending on mixture richness—low voltage indicates lean mixture with excess oxygen, high voltage indicates rich mixture with minimal oxygen.

However, the ceramic element only generates accurate signals when operating at elevated temperatures (approximately 600-800°F minimum). This creates necessity for heating elements that bring sensors to operating temperature rapidly during cold starts rather than waiting several minutes for exhaust heat alone to warm sensors.

This proves critical for emissions compliance as regulations require closed-loop fuel control operation beginning within seconds of engine start—impossible without heater-equipped sensors achieving operating temperature quickly.

The measurement precision dramatically exceeds traditional narrowband sensors. AFR sensors provide continuous proportional output across entire mixture range versus narrowband’s binary rich/lean indication. This enables sophisticated fuel control strategies including lean-burn operation for efficiency, precise cold-start enrichment preventing excessive emissions, and rapid response to throttle changes maintaining optimal mixture during transient conditions.

This enhanced capability creates more complex failure modes including P1135 heater circuit problems that simpler narrowband sensors didn’t experience. However, the overall system reliability and performance advantages prove well worth occasional sensor replacement that any technology using consumable components eventually requires.

Heater Circuit Operation and Critical Importance

The heater circuit consists of several key components:

- Resistive heating element (essentially wire coil) embedded within sensor ceramic element

- Electrical power supply from vehicle battery through relay or ECM control

- Ground connection completing circuit

- ECM monitoring circuitry measuring heater current draw or resistance verifying proper operation

The ECM energizes heater circuit immediately upon engine start applying battery voltage (approximately 12-14.5 volts depending on charging system) to heating element. This converts electrical energy to heat warming sensor element from ambient temperature to 600-800°F operating range within 30-60 seconds. This enables rapid closed-loop fuel control transition critical for emissions compliance and optimal cold-operation performance.

The heater monitoring involves ECM continuously measuring heater circuit characteristics—current draw, resistance, or voltage drop depending on specific circuit design. It compares actual values against expected specifications determining whether heater functions properly.

When measured values fall outside acceptable ranges, the ECM triggers P1135 code. These problematic conditions include:

- Open circuit – infinite resistance from broken heating element or severed wiring

- Short circuit – near-zero resistance from internal short or ground fault

- High resistance – degraded heating element drawing insufficient current

The failure modes prove diverse with distinct frequencies:

Complete heater element breakage (most common failure, approximately 60-70% of P1135 cases) prevents any heating requiring sensor replacement.

Partial degradation where element still functions though at reduced capacity (approximately 20-25% of cases) potentially allows eventual sensor operation through exhaust heat alone though with extended warm-up period.

Electrical system problems (approximately 10-15% of cases) including wiring damage, connector corrosion, or ECM faults where sensor itself remains functional though electrical infrastructure problems prevent proper heater operation requiring wiring repair rather than sensor replacement.

Bank 1 Sensor 1: Location and Function Specificity

The “Bank 1 Sensor 1” designation follows industry-standard nomenclature where “Bank” refers to cylinder bank on V-configuration engines. Bank 1 contains cylinder #1, Bank 2 the opposite bank. “Sensor 1” indicates upstream position (before catalytic converter) versus “Sensor 2” downstream position (after catalyst).

However, RAV4 uses inline four-cylinder engines (except 2006-2012 V6 option) meaning true “bank” distinction doesn’t exist. The Bank 1 Sensor 1 simply represents primary upstream sensor providing main fuel control feedback positioned in exhaust manifold or immediately downstream within 12-18 inches of exhaust ports. This ensures rapid exposure to hot exhaust gases enabling quick sensor response.

The sensor positioning proves critical for function with upstream placement ensuring sensor receives representative exhaust sample before catalytic converter processes gases. Location in high-temperature zone enables rapid sensor warm-up through exhaust heat supplementing heater element operation.

Sensor access typically requires raising vehicle on jack stands or ramps working from underneath. Location proves somewhat cramped though generally accessible using standard tools and specialized oxygen sensor socket (split-side socket accommodating wiring harness that conventional sockets cannot fit around).

The functional distinction between upstream Sensor 1 and downstream Sensor 2 proves important for understanding P1135’s significance:

Upstream Sensor 1 provides primary fuel control feedback directly affecting engine operation. Failures directly degrade drivability, fuel economy, and performance forcing open-loop operation using predetermined fuel maps.

Downstream Sensor 2 monitors catalyst efficiency affecting emissions compliance but not real-time fuel control. Failures primarily affect only emissions monitoring triggering check engine lights without substantially affecting vehicle operation.

This makes P1135 addressing Bank 1 Sensor 1 more urgent than P1136 addressing Bank 1 Sensor 2 (downstream) given the upstream sensor’s critical operational role versus downstream’s primarily monitoring function.

P1135 Code Definition and Related Codes

Understanding P1135’s precise meaning and how it relates to similar codes prevents confusion enabling accurate diagnosis and appropriate repair prioritization.

P1135 Specific Definition

The P1135 diagnostic trouble code specifically indicates “Air-Fuel Ratio Sensor Heater Circuit Malfunction Bank 1 Sensor 1.” The ECM detected abnormal heater circuit operation through monitoring revealing resistance, current draw, or voltage values falling outside programmed specifications.

The malfunction determination requires persistent abnormal condition rather than momentary deviation. ECM typically validates fault across multiple drive cycles or exceeding severity thresholds. This prevents nuisance codes from transient electrical anomalies though ensuring genuine problems receive attention rather than being dismissed as electronic noise.

The detection methodology involves ECM measuring heater circuit electrical characteristics immediately upon engine start and continuously during operation. It compares measurements against lookup tables specifying normal heater resistance (typically 11-16 ohms at room temperature though varying by specific sensor model), current draw (approximately 1-2 amps), or other parameters depending on monitoring strategy.

Deviations indicating problems include:

- Infinite resistance (open circuit from broken heater element or severed wiring)

- Near-zero resistance (short circuit to ground or between heater terminals)

- Substantially elevated resistance (degraded element partially failed though not completely open)

- Insufficient current draw (high-resistance circuit preventing adequate heating element operation)

The triggering conditions typically require fault detection during specific operating conditions (often during initial engine start when heater activation first occurs) persisting across multiple ignition cycles (usually 2-3 consecutive drive cycles) before illuminating check engine light and storing confirmed code.

This validation prevents false alarms from temporary issues while ensuring genuine problems don’t escape detection. However, it means that intermittent problems might not consistently trigger codes creating diagnostic challenges when faults prove intermittent rather than constant.

Related Codes: P1155, P0135, P0420

The P1155 code represents identical heater circuit malfunction as P1135 but affecting Bank 2 Sensor 1—the opposite cylinder bank’s upstream sensor on V6 RAV4s (2006-2012) or potentially second upstream sensor on inline four-cylinder configurations using multiple upstream sensors.

The diagnostic procedures, repair approaches, and cost implications prove essentially identical between P1135 and P1155 with only physical sensor location differing.

When both codes appear simultaneously, this suggests potential systemic problems requiring broader diagnosis:

- Wiring harness damage affecting multiple sensors

- ECM power supply issues

- Less likely coincidental multiple sensor failures

The P0135 code represents OBD-II generic equivalent of manufacturer-specific P1135, indicating identical heater circuit malfunction Bank 1 Sensor 1 though using standardized generic code number versus Toyota-specific numbering.

Some scan tools display P0135 while others show P1135 for identical fault. There’s no functional difference with both indicating same problem requiring identical diagnosis and repair. Understanding that these represent same issue prevents confusion when different information sources reference different code numbers for identical condition.

The P0420 code (catalyst efficiency below threshold) frequently appears alongside or shortly after P1135/P1155 creating diagnostic confusion. However, the codes represent different though potentially related problems.

P1135 indicates sensor heater malfunction preventing proper sensor operation, while P0420 suggests catalytic converter efficiency degradation. However, P1135 causing improper fuel control from disabled sensor can trigger false P0420 codes when catalyst actually functions properly but receives inaccurate oxygen sensor data creating false efficiency calculations.

This makes P1135 repair priority with P0420 potentially self-resolving after sensor replacement restores proper fuel control and accurate catalyst monitoring.

The diagnostic sequence should address P1135 first, then verify whether P0420 persists after sensor replacement before condemning potentially functional catalyst.

Symptoms and Drivability Impact

Understanding how P1135 affects actual vehicle operation beyond just illuminated check engine light helps assess repair urgency and recognize developing problems before code triggers.

Primary Symptom: Illuminated Check Engine Light

The check engine light illumination represents most obvious and often only noticeable symptom with P1135. The amber warning displays steady rather than flashing—flashing indicates severe misfire requiring immediate attention, steady light indicates less critical stored code.

The light remains continuously illuminated once code sets until someone clears codes using scan tool. Simply ignoring light won’t make it extinguish as the fault persists triggering continuous detection and warning generation until underlying problem receives repair.

The emissions test implications prove significant as any stored trouble code automatically fails OBD-II-based emissions testing regardless of actual tailpipe emissions levels. This means P1135 guarantees inspection failure in jurisdictions requiring periodic testing preventing legal vehicle registration renewal or creating traffic violation liability.

Some areas allow temporary waivers for expensive repairs deemed economically unreasonable relative to vehicle value. However, most jurisdictions require actual repair and code clearing before passing inspection making P1135 resolution eventually necessary for continued legal operation in inspection-required areas.

Fuel Economy Degradation

The fuel economy impact varies depending on whether heater failure completely prevents sensor operation versus partial degradation allowing eventual operation through exhaust heat alone.

Complete heater failure preventing sensor reaching operating temperature forces ECM into open-loop fuel control using predetermined fuel maps typically running 10-15% richer than necessary for emissions compliance and catalyst protection. This creates measurably worse fuel economy that owners notice through reduced miles-per-gallon and increased fuel costs potentially reaching $30-50 monthly for typical driving. This creates economic incentive for prompt repair beyond just addressing check engine light.

Partial heater degradation where sensor eventually reaches operating temperature through exhaust heat (though slower than proper heater operation enables) creates less dramatic fuel economy impact. There’s extended cold-operation period before closed-loop transition but eventual normal efficiency once sensor achieves operating temperature.

This creates situations where drivers notice “worse fuel economy when cold” that improves after several minutes warmup. This represents classic indication of heater problems preventing rapid sensor activation though eventually exhaust heat brings sensor online enabling normal closed-loop operation.

The quantified impact for typical RAV4 experiencing complete sensor failure approximates 2-4 MPG reduction from normal 27-30 MPG combined (conventional) or 40-41 MPG (hybrid). This creates annual fuel cost increases of $200-400 for 15,000-mile driving at $3.50/gallon—substantial expense that accumulates making multi-month repair delays economically irrational when repair costs ($150-$350) prove less than several months’ fuel economy penalties.

This creates clear economic argument for prompt P1135 repair rather than indefinite postponement hoping problem resolves spontaneously. It won’t—failed heating elements require replacement, not spontaneous self-repair.

Performance and Drivability Effects

The most noticeable performance symptoms occur during cold operation before sensor reaches operating temperature (if it ever does with failed heater). Symptoms include rough idle, hesitation during acceleration, reduced power, and generally less refined operation compared to normal closed-loop control’s smooth precise fuel delivery.

The symptoms typically prove most pronounced immediately after cold starts progressively improving (if sensor eventually reaches operating temperature through exhaust heat) or remaining persistent (if sensor never achieves proper temperature due to complete heater failure combined with insufficient exhaust heat warming).

The cold-weather exacerbation proves notable with problems significantly worse in winter when ambient temperatures and reduced exhaust heat (shorter trips, more idle time) prevent sensor achieving operating temperature even with partially-functional heaters.

This creates seasonal symptom patterns where problems prove tolerable in summer though increasingly frustrating in winter making seasonal timing considerations relevant for repair scheduling. However, delaying winter repairs into spring/summer proves false economy as continued open-loop operation wastes fuel and risks catalyst damage from extended rich operation regardless of season.

Long-Term Consequences of Neglect

The immediate consequence involves failed emissions testing preventing legal vehicle operation in inspection-required jurisdictions. However, jurisdictions without testing enable indefinite code ignorance though this proves unwise given additional problems that develop.

The fuel economy penalty creates ongoing costs that compound over time. Multi-year neglect costs $600-1,200+ in wasted fuel far exceeding $200-350 repair costs making prompt attention economically rational.

The catalytic converter risk proves most serious. Extended open-loop rich operation potentially causes catalyst degradation from excessive unburned fuel entering catalyst creating thermal stress and carbon fouling reducing catalyst efficiency. This eventually triggers P0420 catalyst efficiency codes requiring $1,000-2,500 catalyst replacement far exceeding simple $200-350 sensor replacement that addressing P1135 promptly would have required.

This cascading failure scenario—ignored sensor problem causing catalyst damage requiring exponentially more expensive repair—creates compelling argument for addressing P1135 promptly preventing secondary damage that procrastination enables.

Systematic Diagnostic Procedures

Proper diagnosis ensures repairs address actual problems rather than wasting money on unnecessary sensor replacements when wiring repairs or other solutions would resolve P1135 at lower cost.

Initial Code Reading and Data Analysis

Step 1: Comprehensive code retrieval using quality OBD-II scan tool (not just basic code reader) retrieving all stored codes (confirmed and pending), freeze frame data showing conditions when P1135 set, and live sensor data observing current sensor operation.

The freeze frame proves particularly valuable showing engine temperature, vehicle speed, and other parameters existing when code triggered. This reveals whether problem occurs during cold starts (most common with heater failures), hot operation (less typical suggesting other problems), or specific operating conditions providing diagnostic clues.

Step 2: Live data observation with engine running (after achieving operating temperature) examining AFR sensor voltage or lambda readings determining whether sensor provides any output (suggesting partial function) versus completely inactive (indicating total failure).

Properly functioning sensors show varying voltage (approximately 0.5V at stoichiometric, ranging 0-1.0V as mixture changes) or lambda readings (1.0 at stoichiometric, varying 0.7-1.3 depending on mixture). Failed sensors show frozen readings or no response to throttle changes indicating sensor not measuring exhaust composition properly.

Electrical Testing: Resistance and Voltage Measurements

The heater circuit resistance testing provides definitive heater element condition assessment. This requires digital multimeter with resistance (ohms) measurement capability and sensor connector disconnected preventing ECM interference.

The test procedure involves:

- Locate sensor connector (typically 6-12 inches from sensor body providing thermal protection)

- Identify heater circuit terminals (service manual or wiring diagram required—typically uses two of four-wire sensor’s terminals)

- Set multimeter to resistance measurement (200-ohm range typically appropriate)

- Measure resistance between heater terminals

- Compare measurement to specifications (typically 11-16 ohms at room temperature though varying by sensor model)

The measurement interpretation:

Infinite resistance (OL/overload on multimeter) indicates open heater circuit from broken element or severed wiring requiring sensor replacement if element open or wiring repair if break occurs in harness.

Near-zero resistance (under 1 ohm) suggests short circuit to ground or between terminals indicating sensor replacement necessary.

Substantially elevated resistance (50+ ohms when specification shows 12-16) indicates degraded element partially failed requiring replacement.

Normal resistance (within specifications) suggests sensor heater element functions properly requiring investigation of wiring, connections, or ECM issues rather than sensor replacement.

The voltage testing at sensor connector (with harness connected, sensor disconnected) verifies ECM provides proper power and ground to heater circuit. This requires back-probing connector (inserting multimeter probes alongside wire terminals without disconnecting) or breakout box if available.

The heater power terminal should show battery voltage (12-14.5V depending on charging system) with ignition on, while heater ground should show near-zero voltage (under 0.5V) indicating proper ground connection.

Absence of voltage suggests wiring problems or ECM fault rather than sensor failure, while proper voltage with improper sensor resistance confirms sensor requires replacement rather than wiring repair.

Visual Inspection and Wiring Verification

The connector inspection proves critical as terminal corrosion represents common P1135 cause mimicking sensor problems. The four-pin connector should separate cleanly (may require release tab pressing), with terminals showing clean silver or gold color without green corrosion or black oxidation indicating no water intrusion, melted plastic (suggesting overheating), or bent/damaged pins.

Cleaning corroded terminals using electrical contact cleaner and fine wire brush/sandpaper often resolves intermittent P1135 codes without sensor replacement. Corrosion creates resistance that ECM interprets as heater malfunction though sensor itself remains functional.

The wiring harness examination involves inspecting visible harness for damage including:

- Insulation cracks exposing copper wire

- Melted insulation from exhaust heat exposure

- Chafe marks from rubbing against chassis components

- Rodent damage (surprisingly common with animals chewing insulation)

Pay particular attention to areas where harness passes near exhaust components or sharp chassis edges creating heat damage or abrasion risk, and where harness routing might create flexing stress from engine movement potentially fatiguing wires through repeated bending.

Any visible damage requires repair using proper automotive wiring techniques (solder and heat-shrink tubing, not crimp connectors or electrical tape) before concluding sensor replacement necessary.

Professional Diagnosis Considerations

Professional diagnosis proves worthwhile when:

- DIY testing proves inconclusive or beyond owner’s capability

- Multiple codes appear simultaneously suggesting complex interrelated problems

- Repairs don’t resolve codes (codes return immediately after clearing)

- Symptoms prove severe requiring immediate attention

The diagnostic fees ($80-$150 independent shops, $100-$200 dealerships) provide value through:

- Manufacturer-specific scan tools accessing deeper data than basic OBD-II readers

- Extensive diagnostic databases identifying known problems and recommended solutions

- Specialized testing equipment enabling definitive diagnosis

- Experienced technicians recognizing subtle patterns that inexperienced owners might miss

However, shop selection proves important. Quality independent shops often provide superior diagnosis at lower cost than dealerships that sometimes default to sensor replacement without thorough investigation when problem proves complex.

This creates situations where dealership charges $350 sensor replacement when $100 connector cleaning would have sufficed. The optimal approach involves researching shops through online reviews, seeking ASE-certified technicians familiar with Toyota vehicles, and explicitly requesting thorough diagnosis rather than immediate parts replacement ensuring repairs address actual problems rather than following shotgun replacement strategies wasting money on unnecessary parts.

Repair Options and Procedures

Understanding available repair approaches helps owners select optimal strategies balancing cost, reliability, and implementation difficulty.

Sensor Replacement: Parts Selection and Procedure

OEM Toyota sensors ($150-$250 from dealers) provide guaranteed compatibility and quality matching original equipment. These sensors undergo extensive testing ensuring proper operation across full temperature and condition ranges.

OEM proves worth premium particularly for critical upstream sensors directly affecting fuel control. Toyota’s engineering and quality control creates sensors reliably lasting 100,000+ miles rather than aftermarket alternatives potentially failing prematurely requiring repeat replacement within 2-3 years.

Quality aftermarket sensors from Denso (OEM supplier for many Toyota sensors), NTK/NGK, or Bosch ($80-$150) provide acceptable alternatives offering 30-40% cost savings versus OEM while maintaining reasonable quality and longevity.

These manufacturers produce millions of sensors annually with ISO certification and testing creating products functionally equivalent to OEM for most purposes. However, occasional fitment issues (connector not quite matching, thread length variations) or early failures (perhaps 15-20% failure rate within 3 years versus 5-10% for OEM) occur at slightly higher rates than Toyota parts.

Budget aftermarket sensors ($40-$80) prove tempting for maximum cost savings though they carry substantially higher failure risk (perhaps 30-40% experiencing problems within 2-3 years) from inadequate quality control, improper specifications, and short service life.

These budget sensors occasionally work perfectly providing excellent value. However, they fail often enough that “savings” prove illusory when considering re-replacement costs particularly if professional installation used initially.

Budget sensors might prove acceptable for very old high-mileage vehicles where long-term reliability proves less critical. However, they represent poor value for newer vehicles where multi-year reliable operation proves important.

The replacement procedure (DIY):

- Safely raise and support vehicle on jack stands providing underneath access

- Locate Bank 1 Sensor 1 in exhaust manifold or immediately downstream

- Disconnect wiring harness connector pressing release tab

- Remove sensor using oxygen sensor socket (split-side socket accommodating wiring harness that conventional sockets cannot fit), applying penetrating oil hours before removal if sensor proves seized

- Inspect new sensor ensuring anti-seize compound on threads (most quality sensors come pre-treated)

- Hand-start new sensor ensuring proper thread engagement without cross-threading

- Tighten to specification (typically 30-35 lb-ft—consult specifications)

- Reconnect wiring harness ensuring positive click

- Clear codes using scan tool

- Drive vehicle 20-30 minutes varied conditions enabling ECM verification

- Rescan for codes confirming P1135 doesn’t return

Wiring Repair: Alternative to Sensor Replacement

When diagnosis reveals wiring problems rather than sensor failure (proper sensor resistance but no power/ground at sensor connector, visible harness damage, connector corrosion), wiring repair proves appropriate avoiding unnecessary $200-$350 sensor replacement when $50-$150 wiring fix resolves problems.

The repair involves:

- Identifying specific failure point (break location, corroded terminals, damaged connector)

- Obtaining repair materials (replacement terminals, heat-shrink tubing, solder, possibly replacement connector)

- Performing proper automotive wiring repair using solder connections with heat-shrink protection rather than crimp connectors or tape that prove unreliable long-term

The connector repair for corroded terminals requires:

- Disassembling connector (carefully removing terminal retention clips)

- Removing corroded terminals (noting wire colors and positions for correct reassembly)

- Cleaning or replacing terminals depending on corrosion severity

- Applying dielectric grease preventing future corrosion

- Carefully reassembling ensuring positive terminal retention and proper seal preventing water intrusion

This proves simpler and less expensive than complete sensor replacement when corrosion represents only problem though sensor itself remains functional.

The harness repair for damaged wiring sections involves:

- Identifying damage extent (single wire break versus multiple wires, length of damaged section)

- Cutting out damaged section leaving clean wire ends

- Stripping insulation exposing clean copper

- Creating proper solder connections (overlapping wires, applying solder creating mechanical and electrical bond)

- Protecting repair with heat-shrink tubing preventing moisture intrusion and providing strain relief

Professional shops charge $150-$300 for harness repairs depending on damage extent and access difficulty. Capable DIYers can perform repairs for $20-$50 in materials saving substantial labor costs though requiring time investment and moderate electrical repair skills.

Cost Analysis: Budgeting for P1135 Repair

Understanding realistic repair costs helps owners budget appropriately and recognize fair pricing versus excessive charges.

Parts Cost Breakdown

OEM Toyota AFR sensor: $150-$250 from dealership parts departments. Online Toyota dealers sometimes offer 10-20% discounts versus walk-in counter pricing making internet shopping worthwhile for cost-conscious buyers accepting 2-3 day shipping versus immediate availability.

Quality aftermarket sensors (Denso, NTK, Bosch): $80-$150 from auto parts retailers (AutoZone, O’Reilly, Advance Auto) or online sources (RockAuto $80-$120, Amazon $100-$140). Pricing variations prove substantial even within brands based on purchase channel.

RockAuto typically offers lowest pricing with slower shipping, while local parts stores charge premium for immediate availability.

Budget aftermarket sensors: $40-$80 from online marketplaces (Amazon, eBay), though quality proves highly variable. Some provide acceptable service while others fail prematurely or never function properly requiring return/replacement consuming time and potentially creating extended vehicle downtime.

Wiring repair materials: $20-$50 for terminals, solder, heat-shrink tubing, dielectric grease, and connector components if needed. This represents one-time purchases that often provide materials for multiple future repairs building useful consumables inventory.

Labor Costs for Professional Installation

Independent shop labor: $100-$150 hourly rates with sensor replacement typically requiring 1.0-1.5 hours book time creating $100-$225 labor charges for routine replacement.

However, seized sensors, difficult access, or combined diagnostic work might increase time to 2-3 hours creating $200-$450 labor charges. Reputable shops should provide estimates before beginning work rather than surprising customers with unexpectedly high bills.

Dealership service: $120-$180 hourly rates (higher in expensive markets, lower in rural areas) with similar 1.0-1.5 hour book time creating $120-$270 labor charges.

Dealership advantages include:

- Factory-trained technicians familiar with Toyota-specific issues

- Access to manufacturer service bulletins

- Warranty coverage through manufacturer’s repair guarantee programs

These benefits potentially worth premium pricing for complex problems though routine sensor replacement rarely requires these advantages making independent shops often better value.

Mobile mechanics: $75-$125 hourly rates with on-site service providing convenience though potentially limited diagnostic capabilities and challenges working in driveways versus professional service bays.

The mobile option proves excellent for confirmed sensor replacement when diagnosis already completed. However, complex diagnostic situations often require shop resources that mobile services cannot provide.

Total Cost Scenarios

Scenario 1: Budget DIY using quality aftermarket sensor ($100), existing tools, DIY installation (1-2 hours work) = $100-$120 total including consumables. Lowest possible cost though requiring mechanical capability and tools accepting potential complications.

Scenario 2: Premium DIY using OEM sensor ($200), possibly purchasing oxygen sensor socket ($20-$30), DIY installation = $220-$250 total. Moderate cost providing OEM quality without professional labor expense.

Scenario 3: Independent shop using quality aftermarket sensor ($120), professional installation (1.5 hours at $120/hour) = $300-$350 total. Mid-range option providing professional quality and warranty coverage without dealership premium.

Scenario 4: Dealership service using OEM sensor ($220), professional installation (1.5 hours at $150/hour) = $440-$500 total. Highest cost providing maximum assurance through OEM parts and factory-trained service.

Scenario 5: Wiring repair at independent shop (2 hours diagnostic/repair at $120/hour, $30 materials) = $270-$300 total. Alternative when diagnosis reveals wiring problems rather than sensor failure, potentially saving versus unnecessary sensor replacement.

Conclusion: Managing P1135 for Optimal RAV4 Performance

The Toyota RAV4 P1135 code represents common though manageable issue indicating AFR sensor heater circuit malfunction requiring systematic diagnosis confirming whether actual sensor failure, wiring problems, or connector corrosion causes code before implementing appropriate repair.

Proper diagnosis often reveals less expensive solutions than immediate sensor replacement that shotgun approach assumes necessary. The code proves most common on third-generation 2006-2012 RAV4s reaching 80,000-150,000 miles as original sensors approach designed service life. Fourth and fifth-generation vehicles also experience this issue at similar mileages creating predictable maintenance requirement that owners should anticipate and budget for rather than treating as unexpected failure indicating poor vehicle quality.

For RAV4 owners encountering P1135, the recommended approach involves:

Prompt diagnosis within days of code appearance (not months of procrastination) preventing fuel economy penalties and catalyst damage risk.

Systematic troubleshooting identifying actual fault through electrical testing and inspection before assuming sensor replacement necessary.

Appropriate parts selection balancing cost and quality (quality aftermarket proving optimal for most applications).

Proper repair ensuring reliable fix rather than temporary solution requiring repeated service.

The investment in proper diagnosis ($0-$150 depending on DIY versus professional) and quality repair ($200-$500 typically) proves worthwhile. This avoids both wasted money on incorrect repairs and continued operation in degraded mode that costs more through fuel consumption and potential secondary damage than prompt proper repair would have required.

The broader context positions P1135 as normal age-related maintenance similar to spark plugs, brake pads, or tires requiring periodic replacement as designed service life limits reach. This doesn’t indicate poor RAV4 quality or reliability.

Oxygen sensor replacement represents entirely normal 80,000-150,000 mile maintenance on essentially all modern vehicles regardless of manufacturer. The RAV4’s exceptional reliability reputation remains valid despite periodic sensor replacements that all vehicles eventually require. Overall ownership costs and repair frequencies remain substantially lower than less-reliable alternatives making RAV4 continue deserving consideration as segment-leading choice for buyers prioritizing long-term durability and reasonable operating expenses.